Flexible Heaters

//Flexible Heaters

Other Customized Electric Heating Elements

- Resistance tolerance

± 10% standard; other tolerance are available

- Leadwire

Teflon insulated, red.

- Dimensional tolerance

± 0.03”if 6” or lese; ± 0.06”if 6.01”to 12”; ± 0.12”if over 12”

GENERAL SPECIFICATIONS

RESISTANCE TOLERANCE:±10%standard; other tolerance are available.

DIMENSIONAL TOLERANCE: ±0.03”if 6” or lese; ±0.06”if 6.01”to 12”; ±0.12”if over 12”.

LEADWIRE:Teflon insulated, red.

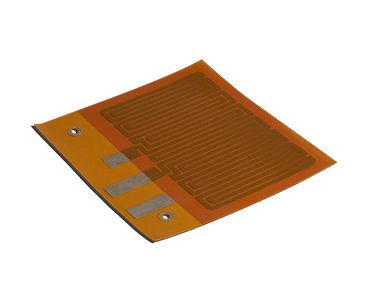

MAXIMUM HEATER THICKNESS ( in inches )

| OVER | OVER LEADS | OVER LEADS | OVER LEADS | OVER LEADS | |

|---|---|---|---|---|---|

| INSULATION | ELEMENT | AWG 30 | AWG 26 | AWG 24 | AWG 20 |

| KAPTON | 0.010ˇ | 0.050ˇ | 0.060ˇ | 0.065ˇ | 0.085ˇ |

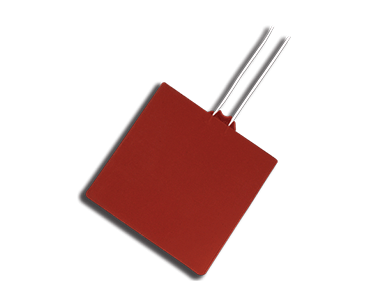

| SILICON RUBBER | 0.02 | 0.070ˇ | 0.080ˇ | 0.090ˇ | 0.120ˇ |

| NOMEX | 0.017 | 0.065ˇ | 0.075ˇ | 0.085ˇ | 0.115ˇ |

| POLYESTER | 0.017 | 0.065ˇ | 0.075ˇ | 0.085ˇ | 0.115ˇ |

“ˇ” Add approximately 0.015” to these dimensions when pressure sensitive adhesive is used.

APPLICATION RESISTANCE

( 1 ) WATER-RESISTANCE

Kapton, Silicon rubber, Teflon and Polyester are water-resistant insulation materials. Take caution to seal around heater edges and leads exit area before operating. Kapton, Nomex and Polyester are oil-resistant, but they must be modified before immersion. YUNG TIEN Co. FLEXIBLE HEATERS are absorbent. Immerse the heater in 40℃water a week, and it will weigh 2.9% more. So the flexible heater must be varnished with fluorine or Silicon rubber before using in high temperature.

( 2 ) DIELECTRIC STRENGTH

0.02mm YUNG TIEN Co. FLEXIBLE HEATER can endure 2500v, and 0.06mm heater con endure 7500v.

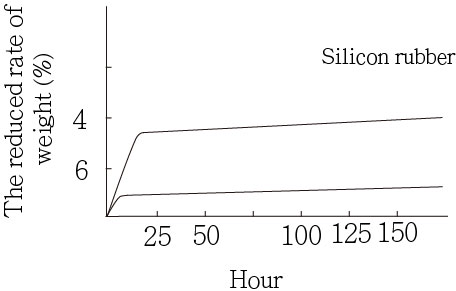

( 3 ) VACUUM STABILITY

In 200℃ and 3 ×10¯6 Torr vacuum, we test the heater and find that there is no free air molecule from the insulation. So YUNG TIEN Co.FLEXIBLE HEATER has good stability in a vacuum. The folloeing list is the weight curvature of YUNG TIEN Co. FLEXIBLE HEATER insulation and Silicon rubber for your reference.

( 4 ) RADIATION RESISTANCE

Kapton, Silicon rubber, Teflon, Nomex and Polyester are radiation resisitant. YUNG TIEN Co.FLEXIBLE HEATER can resist radiant rays to 109 red, and its curvature is the same.

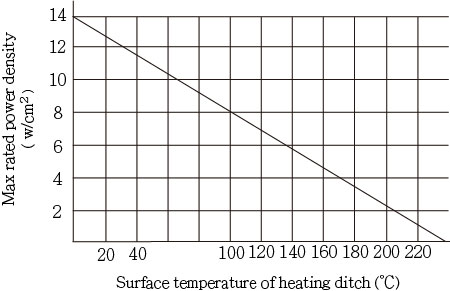

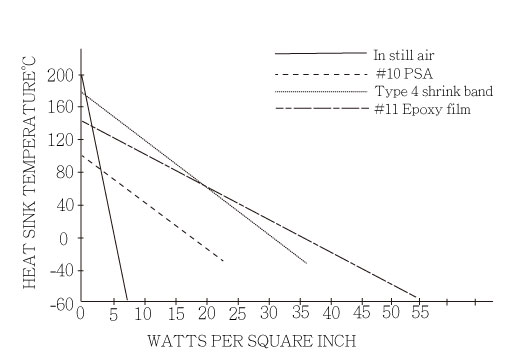

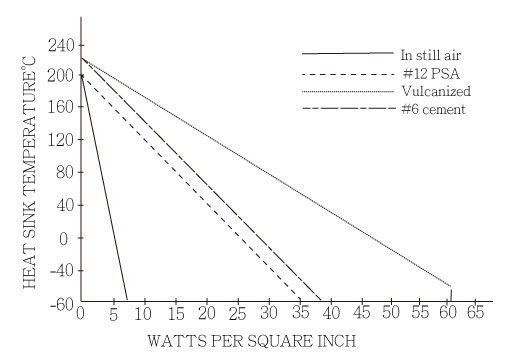

( 5 ) MAX RATED POWER DENSITY CHART

The chart is when heater is, mounted with cement, heated.

( 6 ) UL RECOGNITION

The Silicon rubber and Teflon used in YUNG TIEN Co. FLEXIBLE HEATER is recognized by UL and can be for continuous use to 220℃.

( 7 ) STRENGTH OF INSULATION

| Insulation Item | YUNG TIEN’S (0.15t) |

Silicon rubber (0.4t) |

|---|---|---|

| Initial break strength | 2400 g/mm | 10,000 g/mm |

| Break strength of transmission | 100 g/mm | Min. 1300 g/mm |

| Final pull strength | 1195 kg/cm |

HEATER WATTAEG AND RESISTANCE

The folloeing charts can help you understand heater wattage and valtage.

Maximum watt density for Polyester & Nomex insulated heaters

Maximum watt density for Kapton insulated heaters

Maximum watt density for Silicon rubber insulated heaters

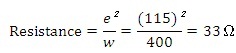

SAMPLE CALCULATIONS

For example, suppose that a Kapton insulated heater must keep the temperature of a cylinder at 60℃. The heater size must be 3”x 6“. Then we estimate that 400 watts of heat are neede, using 115VAC line power. What resistance should be required, and how to mount the heater? Please take the following infor-mation for reference:

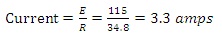

1. DETERMINE THE RESISTANC

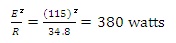

The nearest available resistance is 34.8Ω, so the actual wattage is

2. DETERMINE THAT LEADWIRES ARE SUITABLE FOR THE CURRENT

MAX CURRENT FOR HEATER LEADS

| Leadeire AWG | 20 | 24 | 26 | 30 |

|---|---|---|---|---|

| Max amps | 7 | 4 | 3 | 1 |

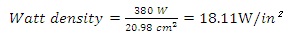

3. CALCULATE WATT DENSITY

The watt density of a heater is the total wattage divided by the effective elemet area. In this example, the area is 20.98 in², so

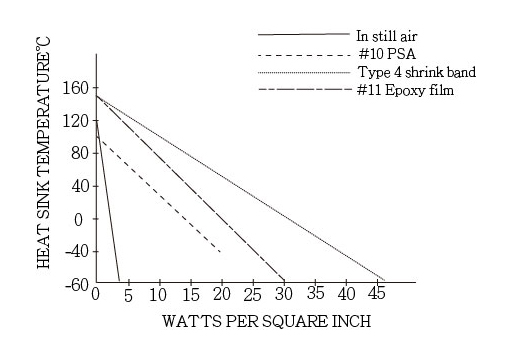

4. CHOOSE THE MOUNTING METHOD

Kapton insulated heaters are checked each method at 60℃, #10 PSA is rated to about 9 W/in², shrink bands to22 W/in², #11 epoxy film to 29 W/in². We suggest you to choose shrink band.

MOUNTING METHODS

1. PRESSURE SENSITIVE ADHESIVE ( PSA )

For easy installation on flat surface, Pressure Sensitive Adhesive may be used with lower watt densities. Heaters should have aluminum backing when PSA is used at higher temperature ( more than 170℃. ) #10 PSA, applied to Kapton, Nomex and Polyester, is suitable forvacuum enviromants; #12 PSA, applied to Silicon rubber and Teflon, is not suitable for vacuum, but con be used on slightly curved surfaces.

| Heater insulation | Temperature range | |

|---|---|---|

| # 10 PSA | Kapton, Nomex | -32 ~ 100℃ ( -25 ~ 212℉ ) [ to 149℃with aluminum backing ] |

| # 12 PSA | Silicon rubber | -62 ~ 177℃ ( -80 ~ 350℉ ) [ to 204℃with aluminum backing ] |

2. CEMENTS

Cements and epoxies allow higher watt densities and mounting on curved surface, but are more difficult to use than PSA. Generally speaking, we recommend either # cement or # 11 epoxy film. # 6 cement will vulcanize at the room temperature, requiring light pressure (15 SPi)but no heat to apply. 3 Oz closed a tube, can cover 6 to 9 square feet. # 11 epoxy film closed to mount the heater needs temperature to 163℃ ( 325℉ ) and pressure to 250 psi.

| Heater insulation | Temperature range | |

|---|---|---|

| #6 RTV Cement | Polyester, Nomex ilicon rubber Mica, Kapton |

-62 ~ 235℃ ( -80 ~ 455℉ ) |

| #11 Epoxy film | MICA | -100 ~ 1800℃ ( -148 ~ 3208℉ ) |

3. SHRINDK BAND

For mounting heaters on cylinders, shrink bands are better. They are prestrecthed film strips with adhesive on both ends for binding a heater on the cylinder. When heated, the band shrinks and tightly binds the heater without using adhesives. Heaters can be easily removed without damage.

| Heater insulation | Temperature range | |

|---|---|---|

| Type 3 Mylan | Kapton,Nomes Silicon rubber |

-32 ~ 149℃ ( -25 ~ 300℉ ) |

| Type 4 Kapton | Kapton,Nomex Silicon rubber |

-32 ~ 177℃ ( -25 ~ 350℉ ) |

| Type 5 Silicon rubber | Kapton,Nomex Silicon rubber |

-32 ~ 230℃ ( -25 ~ 440℉ ) |

4. SPECIAL METHODS

( 1 ) MECHANICAL CLAMPING:

It allows higher war densities to clamp a heater to its sink. When clamped, Nomex and Kapton must have aluminum backing.

( 2 ) VULCANIZATION:

Put Silicon rubber directly to metal parts under heat and pressure. Vulcanization can give higher watt densities and longer heater life.

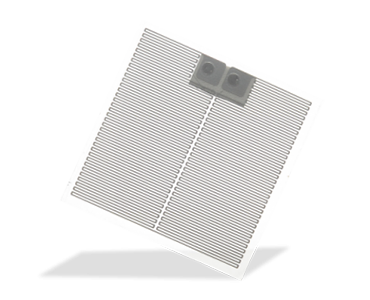

INSTANCES

They can be applied to dehumidify the electric box, heat cups and IC wafer, or food warming bag, etc.

Have a look at the practically applied products. ~ go

This heating element can be customized as per your requirements.

We welcome your inquiry. Thank you for taking the time to visit us online.